| Click to view enlarged image |

|

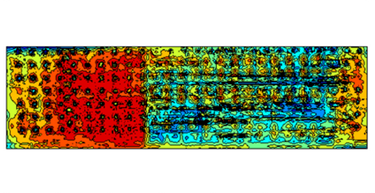

Colorized thermal map of heated plate.

|

|

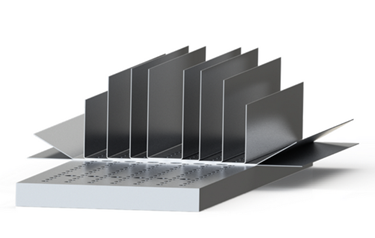

SolidWorks rendering of heat sink.

|

|

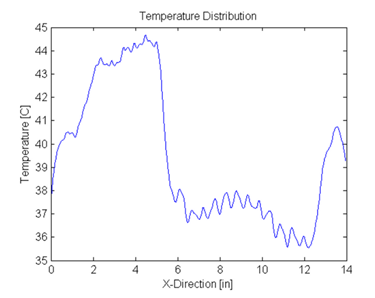

Temperature distribution as a function of x-location on the plate.

|

|

Heat Sink

Completed: 2014-03-20

Collaborators: Kris Li and David Tompkins

In this lab, our team was to design a heat sink for a metal plate. This metal plate would be heated by an electric current and be placed in a wind tunnel to induce forced convection. Our task was to dissipate heat on the plate for the largest area possible. Evaluations were favorable for slow wind speeds, high electrical power, and high heat dissipation. Temperature readings were taken through a thermal imager. This lab served to test our knowledge of heat transfer, to complement a course my mechanical engineering class was taking at the time, Heat and Mass Transfer.

Our team’s plan was to create as much surface area as possible for our heat sink to maximize convection heat transfer with the surrounding air. We chose to use thin sheets of aluminum alloy with a high thermal conductivity to maximize area and minimize mass. To keep under the mass limit of 150 g, we would not have our heat sink span the entire area of the plate, but put it near the back where the effects of the forced convection from the wind tunnel would have the least effect.

Our design implemented a fan-like fin geometry. These fins were spaced out in order to provide maximum “breathing room†for the sink to increase fin efficiency.

To analyze our design, we ran a test in the wind tunnel. After 10 minutes (where the plate would reach steady state temperature distribution), we used a thermal reader to take a temperature reading of the plate. We used a MATLAB script to read the image produced by the reader to determine the success of heat dissipation.

|